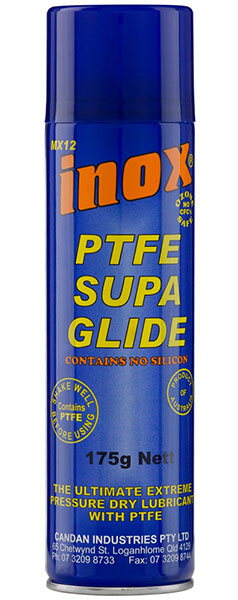

MX12 PTFE Supa Glide

A fast drying – resin bonded, water proof & Abrasion resistant polytetrafluoroethylene dry film lubricant coating for timber, glass, metal, plastic, rubber and most other surfaces.

Product information

INOX-mx12 PTFE SUPA GLIDE is a fast drying, resin bonded polytetrafluoroethylene dry film lubricant for the coating of timber, metal, plastic, rubber, glass and most other surfaces.

It is designed for low-friction, light load repetitive stresses that allows moving parts to wear longer, work harder and require less maintenance. Has applications where other conventional sintered PTFE coatings cannot be considered.

Key features

- Excellent lubrication qualities

- Good surface adhesion

- Hard abrasion-resistant surface

- Clean and easy to apply

- Thin film

- Longer wear life than pure PTFE coatings

- Cures at room temperature

- Inhibits corrosion

- Doesn’t wash off with water

- Resists contamination from dirt and dust

- Life-long lubrication in many applications

Application & Uses

Surface preparationion: Before applying INOX-mx12 PTFE SUPA GLIDE, the surfaces sould be clean, dry and free of contaminants such as oil, grease, dust or powder. A light sanding with 120 grit sandpaper or emery cloth followed by a solvent wipe and air dry is usually sufficent. More critical applications requiring optimum adhesion, the following pretreatments are suggested.

Wood, steel, stainless steel, aluminium, copper alloys, rubber, plastic & glass

Sand lightly and wipe clean

- Degrease or sandblast

- Degrease, sandblast or anodize

- Degrease, sandblast and/or acid etch

- Clean with a solvent that will not effect the substrate

INOX-mx11 Chain & Brake Clean is a good degreaser for cleaning all metals, glass and some plastics. It dries very quickly and leaves no residue.

NB. DO NOT USE TO CLEAN RUBBER PRODUCTS. INOX-mx12 PTFE Supa Glide is recommended for :

- Sliding door, window and curtain tracks

- Sailtracks

- Garage/factory roller door tracks

- Truck/trailer side curtain tracks

- Moving furniture parts

- Piano action parts

- Flexible inner cables

- Solenoid plungers

- PTO couplings

- Pulleys & open gears

- Winches and cables

- Metal, plastic and neoprene bushes

- Saws & guillotines

- Metal punching/stamping machines

- Looms

- Work surfaces for work tables/sewing machines

- And any other sliding or turning surfaces that require a high grade, hard wearing dry lubricant.

Curing time: INOX-mx12 PTFE SUPA GLIDE will cure at room temperature.

Coatings are touch dry in about 5 minutes and dry enough to handle in 20 to 30 minutes depending on the film thickness.

Optimum hardness for the best lubrication operation is 2 hours. It is strongly advised to allow 2 hours from application to use for the best long term results.

High humidity may increase opacity or blush and exposure to strong sunlight may cause darkening, but these will not effect the coating performance.

IMPORTANT NOTICE: INOX-mx12 applications must be fully cured (approx 2 hrs) before they can be used. if is not cured properly the coating may rub off or stick to another surface prematurely

INOX® QUALITY PRODUCTS “There is no substitute for Quality”